Factory Automatic Galvanized Steel C/Z U Purlin Roll Forming Machine With CE Certificate

Roof Truss C Z Purline Making Machinery feature:

1) Take continuous production,there is no need to change the rollers in rough-forming section.

2) steel frame roll forming machine finished with good flatness bending pressure performance is good,

automatic fixed-length cutting, automatic punching, high degree of automation, quick and easy

installation,

3) the product can be used as medium-sized industrial and civil buildings the main force structure, such as

factories, warehouses, machine garages, hangars, exhibition halls, theaters, stadiums, fairs Shed roof and

wall flat load bearing support.

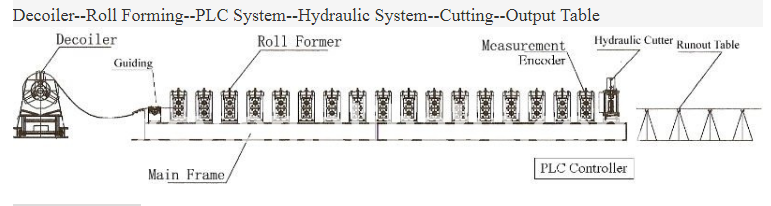

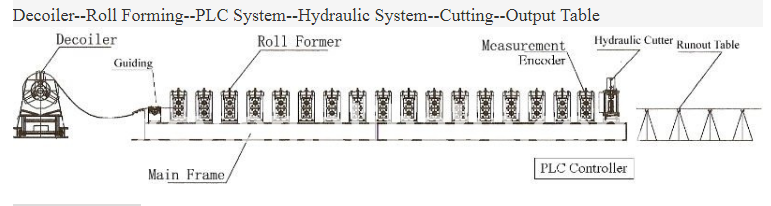

1. Component

| No. | Name | Unit | Qty |

| 1 | Decoiler | set | 1 |

| 2 | Entry Beach | set | 1 |

| 3 | Main Machine for roll forming | set | 1 |

| 4 | Cutting System | set | 1 |

| 5 | punching | set | 1 |

| 6 | Output Table | set | 1 |

| 7 | Control System(PLC) | set | 1 |

| 8 | hydraulic station | set | 1 |

NOTE: All technical parameters can be changed according to user s need, and only as a reference.

2. C Z Purlin Roll Forming Machine Components specification

Decoiler

1) Features:

Mandrel and basement are the two components of the decoiler, the mandrel is shrinking expanding by mechanical device manually, after fix coil to mandrel, then put back the coil with mandrel together to basement.

2) Power: None

3) Power of the open and closure of segments: Mechanical

4) Power of rotation of segment: Pull by forming system

5) Number of segment: 4

6) Range of segment expansion: 480 ~ 520mm

7) Height of center of the mandrel: 0.65m

8) Feeding speed with push: 0~30m/min

9) Approximate Size: 1.5 m * 1.1m *1.2 m

10) Speed control: By mechanical brake

11) Methods of operation: Manual.

Material Feeder

1) Features: Ensure smooth& precise material feed.

2) Components: steel plate platform, two pitching rollers, position stopping block.

3) The coil is guided in the correct position and passed to the roll forming equipment.

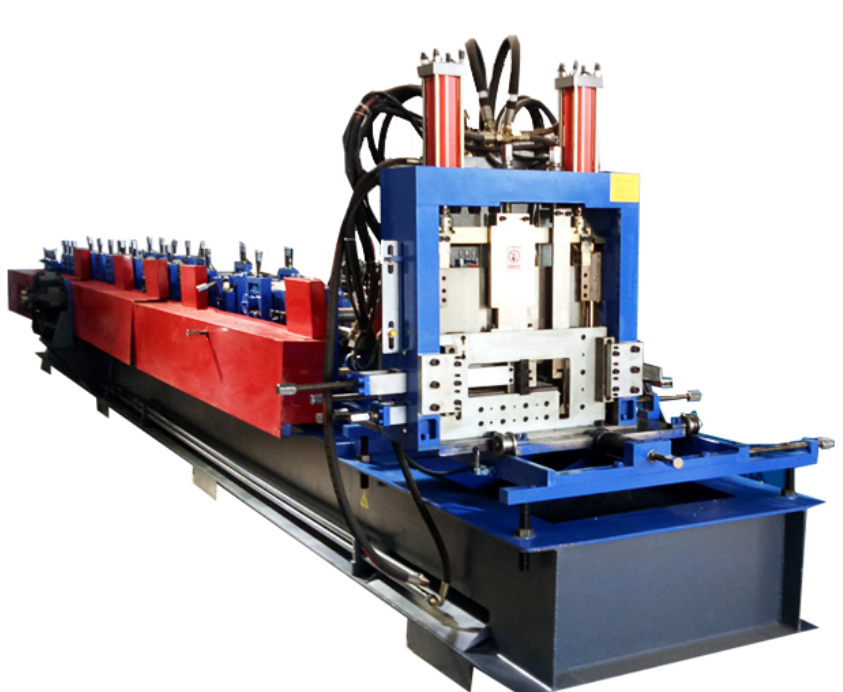

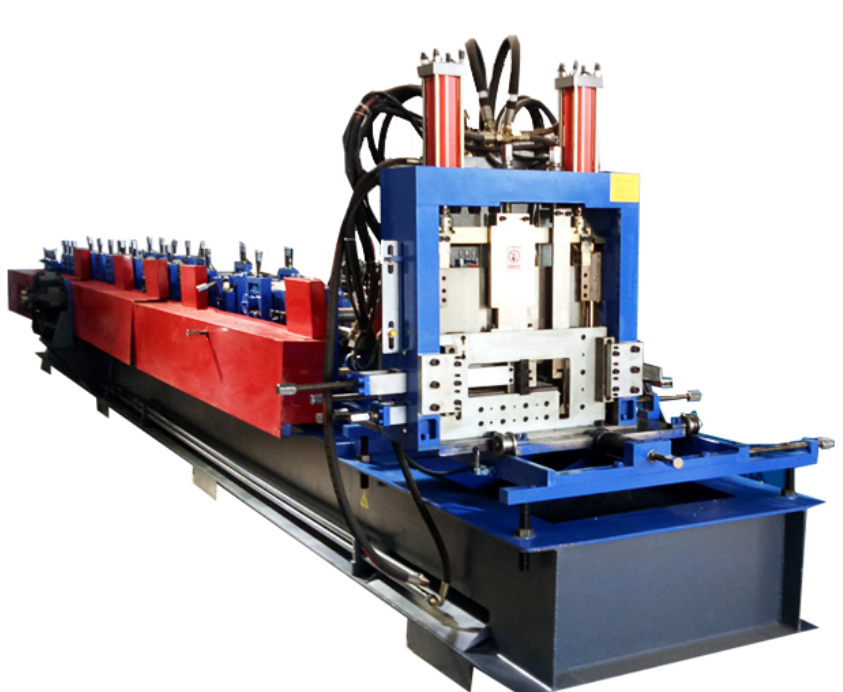

Main colour coated roofing sheet machine part

1) Rollers: design by senior engineers with Auto-cad software, manufactured with 45# high grade steel by CNC machine tools and coated with hard chrome

2) Shaft:70mm manufactured with 45# high grade steel by CNC machine tools

3) Supporting frame: steel wallboard to guide the forming station bearing basement

4) The finished products will change if using different material and thickness

5) Driving of machine:by one inch chain

Hydraulic cutting

1) Function: cutting action is controlled by PLC. The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start.

2) Power supply: hydraulic station

3) Frame: welding steel frame

4) Stroke switch: non-contact photoelectric switch

5) Cutting before forming: cut the sheet after roll forming to required length

6) Length measuring: automatic length measuring

(5)Encoder

The counter gauges length, and modulates pulses.

(6)Simple Stack

It is used for loading the formed plate.

Product Paramenters

| | | Type | GI&PPGI |

| Thickness | 1.5-3mm |

| Yield Strength | 235Mpa to 350Mpa |

| | | Operation | Manual/ Hydraulic for option |

| Weight Capacity | 5Tons |

| | | Roller Station | 18 rows |

| Diameter of Shaft | 80-90mm |

| Material of Rollers | Bearing steel |

| Material of shaft | 45# steel with chrome 0.05mm |

| Transmission | Chain |

| | | Operate | Automatic Hydraulic |

| Blade material | Cr12MOV |

| | | Pump motor for cutter | 7.5KW |

| Main Motor | 11KW |

| Voltage | 380V 50Hz 3 Phase |

| | | Electric Box | PLC control system , Inverter |

| Language | English / Chinese |

| 7 | Speed | 15-30M/min |

3. Working flow:

4. Features of CZ Purlin Roll forming Machine:

C/Z purlin interchangeable rollformer can produce C, Z profiles. Produce from C to Z purlin by switch one side roller, only need about 15 minutes. This machine also can adjust roller horizontal distance to achieve C or Z purlins of the width with high precision automatic. And also save time and increase production.

5. Our service:

Packing Method

Main machine is nude; the computer control box is packed by carton box

Transportation

All machines need one 40 feet container to hold

Payment Term

30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment

Delivery Time

Within 40 days after receiving deposit

Service &Warranty:

1). We provide our customers with 24 months’ warranty.

2). Any parts damaged due to quality problem shall be changed for free within the first two years.

3). Technical guide is provided during whole life of the machine.

4). Oversea services will be provided but any cost thus incurred will be paid by the buyers.

Product Tags:

|

|

Automatic Galvanized Steel CZ U CE Purlin Roll Forming Machine Images

|